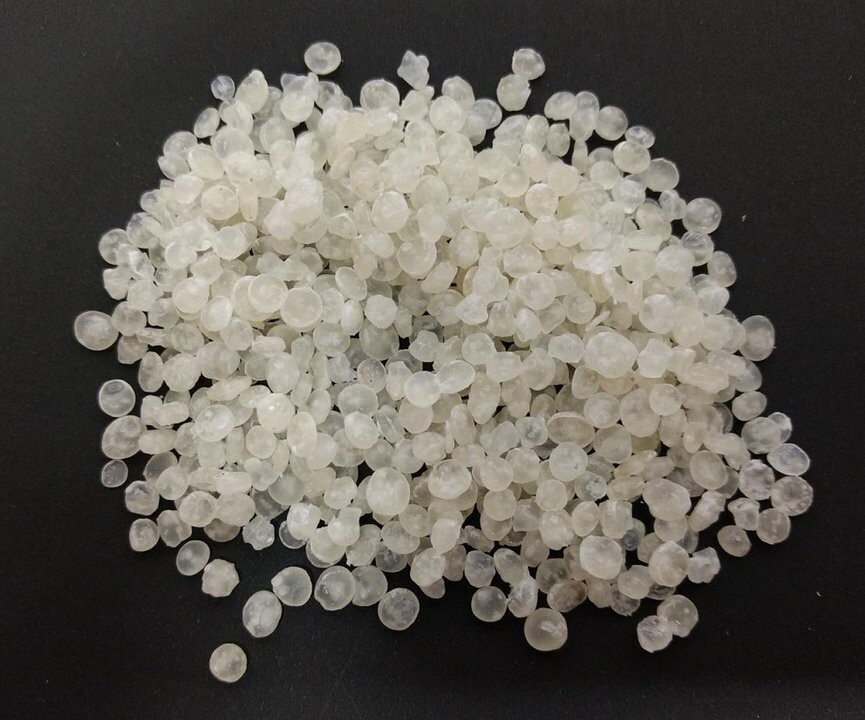

A team of researchers from the National Council for Scientific and Technical Research (CONICET) is advancing the development of biodegradable bags from cassava starch. Through this project, bioplastics are obtained for distribution throughout the country from a regional raw material, which reduces import costs and environmental impact. The initiative was born thanks to an agreement with the Misiones-based company Plastimi SRL, a company dedicated to the manufacture of plastic packaging. The project, led by Cristina Area and Pamela Cuenca, is carried out at the Institute of Materials of Misiones (IMAM, CONICET-UNAM) and involves the participation of the Preservation and Packaging Group (GPE) and the Pulp and Paper Program (PROCYP). The importance of this development lies in the fact that no material of this type is currently manufactured in the country. To meet the demand for biodegradable products, the Misiones-based company imports a resin obtained from corn starch from Europe. More efficient technology The objective of the agreement is to develop an efficient technology and a novel formulation to produce the pellets (small pearls or granules that serve as raw material for the industry).

This project not only seeks to generate innovative material, but also transferable technology. CONICET explains that the development of the material and manufacturing technology will be key to transferring it to the company, promoting the addition of value at the source of local raw materials and reducing the environmental impact generated by petroleum-derived plastics. In addition to packaging, the team is also working on obtaining materials for agricultural inputs, such as mulching films, from biodegradable polymers used in crops in the province. Now, the focus is on improving the properties of the materials and, at the same time, contributing to mitigating the environmental impact of the forestry industry itself.

Why is cassava used? Cassava was chosen as a raw material due to its relevance to the regional economy of Misiones. Commercial materials of this type are usually made from potato or corn starch in other countries, with the latter being the most popular. These are materials intended to produce flexible products, such as bags and films. In this way, a contribution is made to the circular economy approach by using additives obtained from lignocellulosic industry waste, such as micro and nanocellulose and derivatives of rosin, a resin obtained from pine.